Heating Equipment

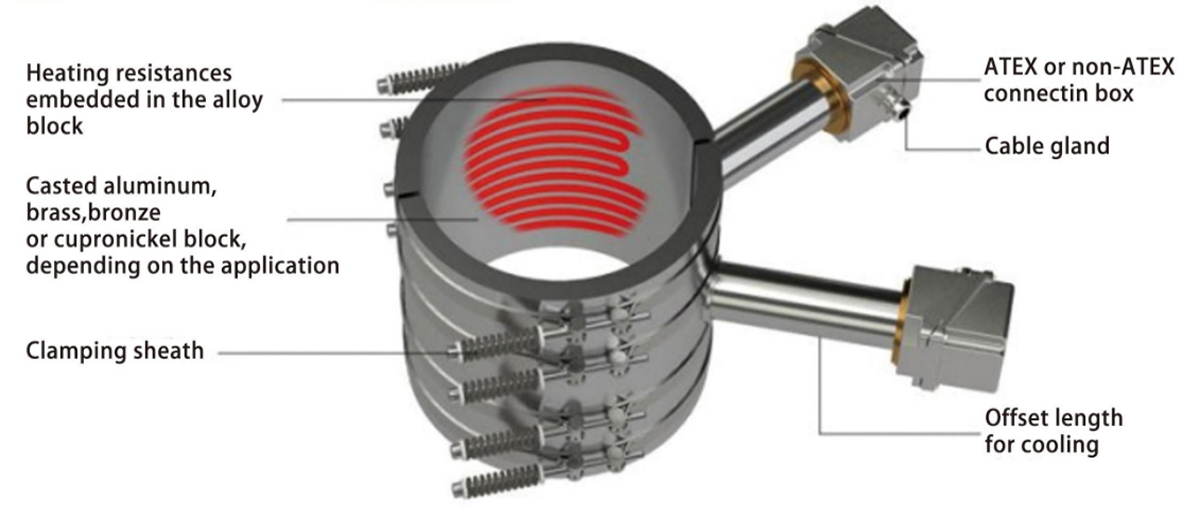

The cast aluminum extrusion mold heating element is a high-performance electric heating component specially designed for plastic extrusion machinery, injection molding machinery, and rubber processing equipment. This heating element uses high-quality alloy electric heating wires as the heating body and is precisely processed and cast into an aluminum alloy or bronze housing to form an integrated heating structure.

The cast aluminum extrusion mold heating element has excellent thermal conductivity, uniform heating effect, and good mechanical strength. It not only ensures uniform heating of plastic raw materials during the extrusion process but also effectively extends the equipment lifespan and improves production efficiency.

This product supports customization according to customer requirements. It offers various voltage levels, power capacities, sizes, structural forms and installation methods to meet the needs of diverse complex working conditions.

Product Parameter

|

Project |

Parameter Range |

|

Voltage |

110V / 220V / 380V / Customizable |

|

Power Density |

2.5 — 5.0 W/cm² (Customizable) |

|

Size Range |

Customized according to the drawing (Inner diameter 50mm - 1000mm and above are all possible) |

|

Material |

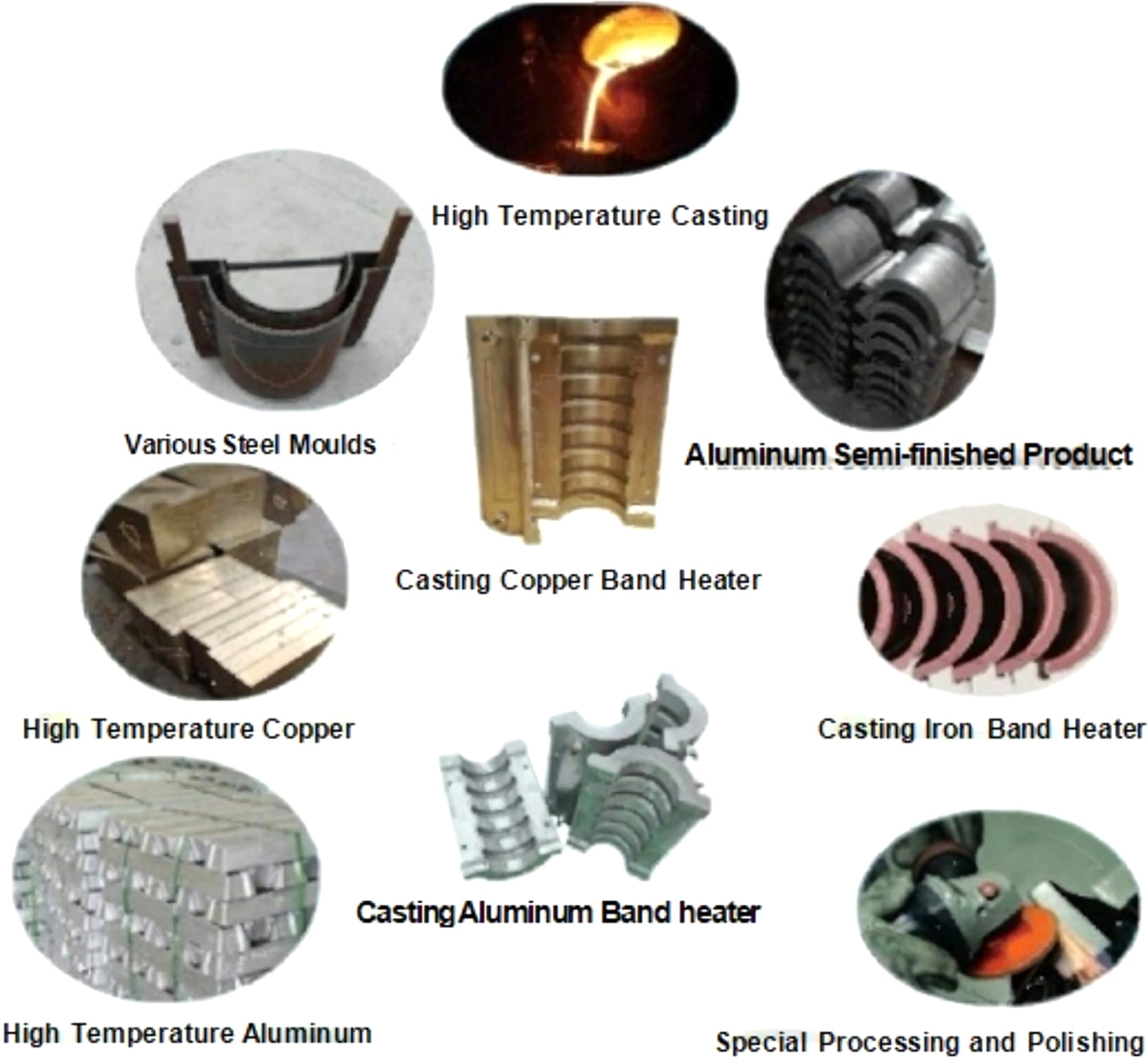

Aluminum alloy, Bronze |

|

Heating Method |

Embedded alloy electric heating wire, uniformly cast in |

|

Working Temperature |

Normal ≤ 350℃, Special conditions ≤ 450℃ |

|

Installation |

Fastening of bolts / Clamping of clamps / Installation of flanges |

|

Additional Functions |

Internal thermocouple, temperature controller can be included, supports multi-point temperature monitoring |

Product Advantages

Uniform heating: The overall casting process is used to avoid local overheating or excessive temperature differences.

Excellent thermal conductivity: Aluminum alloy or bronze materials possess extremely good thermal conductivity, resulting in high thermal efficiency.

Sturdy structure: Cast as a whole, with high mechanical strength and excellent durability.

Long service life: Utilizing imported high-temperature electric heating elements and high-quality insulating materials, it is durable and reliable.

Customization flexibility: Design can be tailored according to the size, voltage, power and shape of the customer's equipment.

Easy to install and maintain: Fixed by bolts or flanges, with convenient disassembly and assembly.

Customization capability

We can offer the following customized services based on the actual working conditions of our customers:

Size customization: Circular, semi-circular, square, plate-like and other structures, with diameters ranging from 50mm to over 1000mm.

Material selection: Aluminum alloy (lightweight, fast heat conduction), Bronze (better corrosion resistance).

Power/ Voltage: 110V / 220V / 380V or other voltages. Power is designed according to the requirements of the mold.

Temperature control method: It can be equipped with a built-in thermocouple (K/J type) or a temperature control probe, which, together with the control system, enables precise temperature control.

Surface treatment: Anodizing and applying a wear-resistant coating to enhance corrosion resistance.

Application Areas

Plastic extrusion machinery: Die head heating, mold temperature control

Injection molding machinery: Mold heating, nozzle heating

Rubber processing equipment: Hot press machine, vulcanizing machine heating

Chemical industry: Reaction vessels, pipeline insulation heating

Other industrial equipment: Suitable for processes requiring high power and uniform heating conditions

Cartridge Heaters Construction

Cast-in Heaters Producing Progress

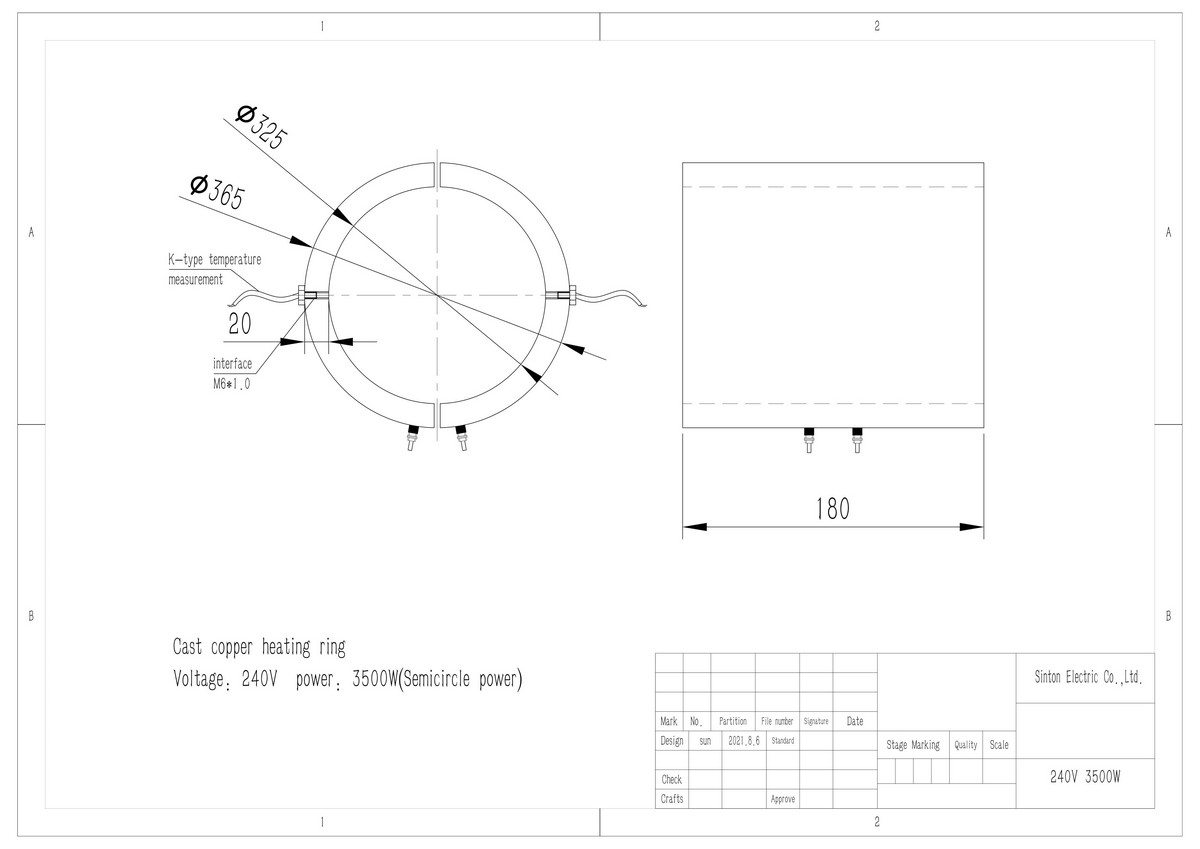

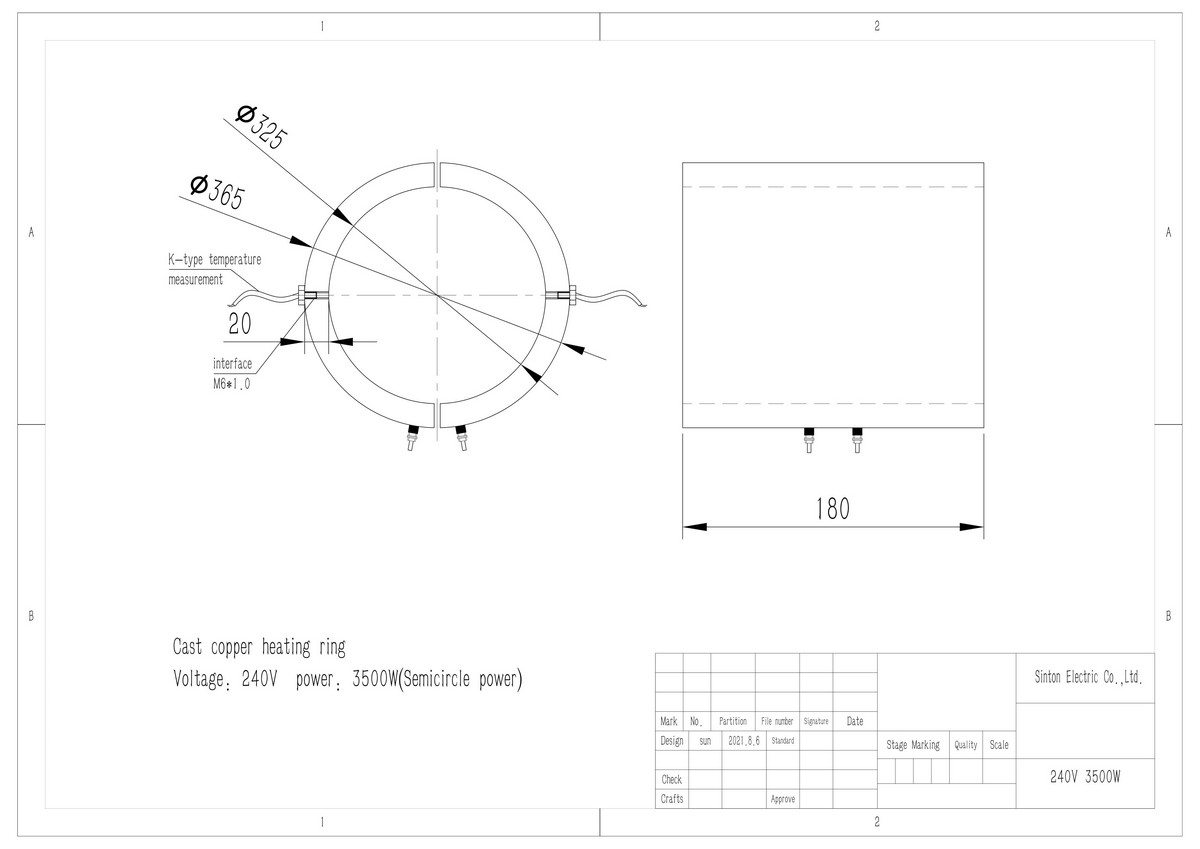

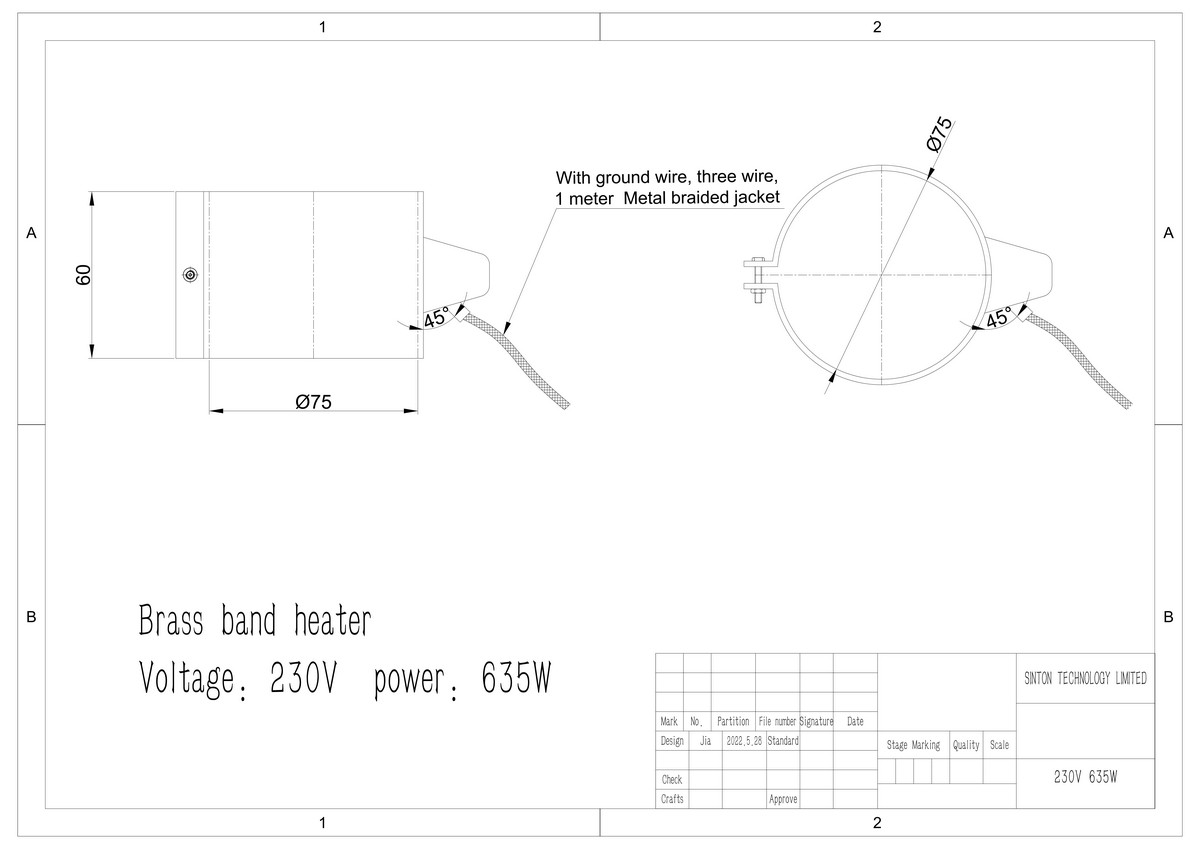

Product drawing

| 3.5kw Cast copper heating coil model |

230v2300w Cast aluminum heating coil model |

635w Brass heating coil model |

|

|

|

Shipment

provides customers with quality and safe transportation.

Available Duct Space and Dimensional Compatibility Before integrating an air duct heater into an existing ventilation system, a comprehensive evaluation of avai...

READ MOREOn February 10, Sinton Group successfully hosted its 2025 Annual Summary and Awards Ceremony alongside the 2026 Chinese New Year Gala under the theme “Moving Fo...

READ MOREHeating Element Configuration The configuration of heating elements within an air duct heater plays a fundamental role in determining airflow resistance and pre...

READ MORETemperature Control Mechanisms in Explosion Proof Oil Circulation HeatersThe temperature control in Explosion Proof Oil Circulation Heaters is a critical comp...

READ MORE1. Thermal Oil Compatibility The Oil Circulation Heater is designed to accommodate a wide range of thermal oils, each with distinct chemical compositions, visco...

READ MORE