Heating Equipment

The crawler-type heating pad is an innovative heating device. It adopts a crawler-type design and can flexibly adhere to different surfaces, providing a uniform and efficient heat application experience. The product combines modern technology with ergonomics and is suitable for various scenarios such as home, medical care, and outdoor use. Through adjustable temperature control and safety protection mechanisms, it provides users with a comfortable and convenient heating solution.

Features:

1. Flexible track design: The unique track structure flexibly adheres to body parts or object surfaces, ensuring even heat distribution.

2. Intelligent temperature control system: Supports multi-level temperature adjustment (usually 3 to 5 levels), allowing users to precisely set according to their needs.

3. Rapid heating technology: Utilizing highly efficient heating elements, it can quickly reach the set temperature within 30 seconds.

4. Detachable fabric cover: The outer fabric cover is made of skin-friendly material and supports disassembly and cleaning to maintain hygiene.

5. Portability and energy storage functions: Some models support power supply from mobile power banks, making them suitable for outdoor use. Built-in battery is optional.

6. Multiple safety protections: Built-in overheat protection, short-circuit protection and automatic power-off function ensure safe use.

Advantages:

1. Efficient hot compress: Compared with traditional heating pads, the crawler design has a larger coverage area and better hot compress effect.

2. Multi-scenario applicability: It is suitable for various uses such as home physiotherapy, outdoor warmth preservation, and medical assistance.

3. Energy conservation and environmental protection: Low-power heating technology is adopted to reduce energy waste.

4. Strong durability: High-quality materials and craftsmanship extend the product's service life.

5. User-friendly: Simple operation, suitable for users of all ages, especially the elderly and those undergoing sports rehabilitation.

|

Parameters |

Description |

|

Product name |

Tracked heating pad |

|

Model |

CHP-2025 |

|

Size |

60cm x 40cm (Customizable) |

|

Weight |

Approximately 800g (including the cloth cover) |

|

Material |

Skin-friendly cotton fabric cover + high-strength PVC track base material |

|

Power |

50W |

|

Voltage |

220V AC / 5V DC (mobile power mode) |

|

Temperature range |

30°C - 60°C (±5°C) |

|

Heating time |

It heats up rapidly within 30 seconds |

|

Battery capacity |

5000mAh (optional) |

|

Usage time |

2 to 4 hours (Battery mode, depending on the temperature setting |

|

Security certification |

CE, RoHS, FCC |

|

Warranty period |

One year |

Application:

1. Home physiotherapy

It relieves muscle soreness and joint stiffness, and is suitable for the elderly and people who sit for long periods.

It promotes blood circulation, improves cold constitution and has a remarkable effect on keeping warm in winter.

2. Medical assistance:

In combination with physical therapy, it is used for the hot compress needs in rehabilitation training.

Relieve chronic pain, such as lumbar intervertebral disc protrusion and rheumatic pain.

3. Outdoor activities:

The portable design is suitable for scenarios such as camping and hiking, providing mobile warmth.

It can be used for physical protection of outdoor workers in cold environments.

4. Other innovative applications:

It is applied to pet insulation pads to provide a comfortable resting environment for pets.

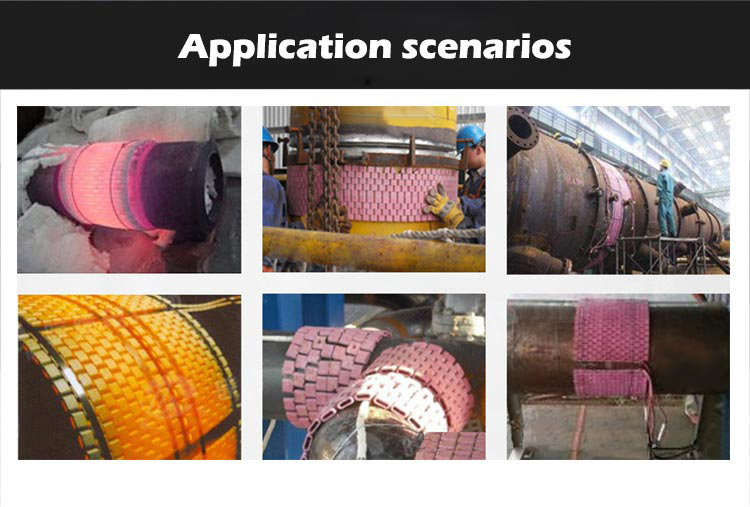

It is used for insulation or preheating of small equipment in the industrial field to meet specific process requirements.

details

Technical specifications:

1. Electrical strength: 2000V/1 min

2. Thermal insulation resistance: >5MΩ

3. Maximum operating temperature: 1050℃

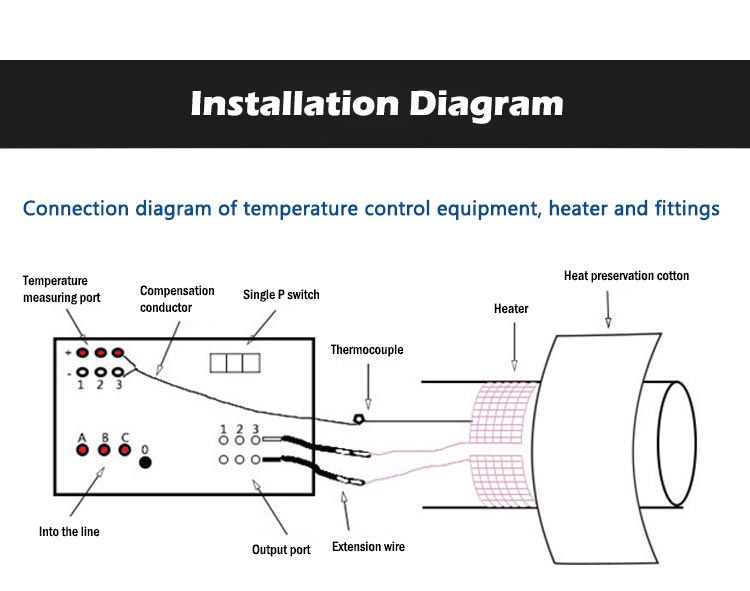

When the user selects the pipeline weld heat treatment equipment, first choose the heater suitable for the workpiece weld (rope or crawler or other types), and then choose the appropriate weld heat treatment equipment according to the number of heaters used once. Portable 30-120KW temperature control box can be used for on-site pipeline heat treatment, such as the weld of the heat treatment workpiece is relatively large. For example, large container ring joint, please choose 180-360KW temperature control cabinet, please leave a certain margin space when purchasing, try not to use full load, and then with heat treatment auxiliary materials (connecting wire, compensation wire, thermocouple, insulation cotton, etc.) can be.

The complete metal component heat treatment equipment consists of three parts, namely, ceramic electric heater, temperature control box and auxiliary materials.

1.Ceramic electric heater: that is, the heating element, is the source of heat when the workpiece is heated.

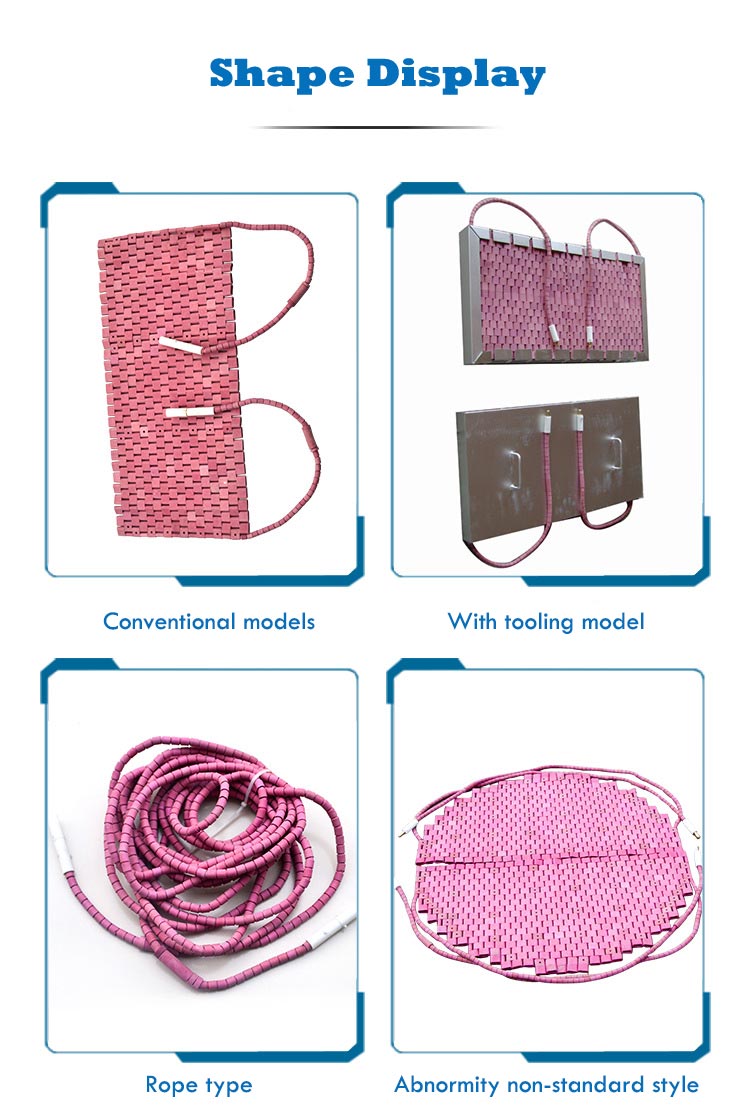

Our company provides you with a variety of models and specifications, they have different characteristics, performance is not the same. Such as LCD type track heater, SCD type rope heater, NJ type internal heat frame heater, etc., generally require the user to choose according to the shape, thickness and required temperature value of the heated workpiece.

2.Temperature control box: It is matched with ceramic electric heater to provide power for ceramic electric heater and control its working state to achieve the purpose of temperature control.

The temperature control box is equipped with a temperature controller to control and measure the temperature of the workpiece, and the temperature recorder is configured to record the temperature curve of the workpiece in real time for the user to file. At present, our company provides users with a variety of models and specifications of temperature control box, such as ZWK series intelligent temperature program control box, DWK series computer temperature control box, LWK series temperature control box, etc. When selecting the user needs to choose the ideal and practical temperature control box according to the heating range, heating process requirements and on-site requirements.

3.Auxiliary materials:

Mainly KJ type quick extension wire (temperature control box and heater distance connection line, It is also used in series for 36V, 55V, 110V and other heaters, and is equipped with a quick connection plug), thermocouple (temperature sensor, used to measure the temperature of the heated workpiece), compensation wire (the connection line between the thermocouple and the temperature control box), aluminum silicate high temperature insulation cotton (to prevent heat dissipation).

Installation and use:

1.According to the size of the equipment and the workpiece, a single component or multiple components can be evenly arranged, and the fixing method during installation can be tied with stainless steel wire or stainless steel belt bent into a fastening ring, and then fastened with screws.

2.From the temperature requirements and energy-saving considerations, the heater should be covered with insulation layer material 6~8cm and temperature controller.

3.The heater is not allowed to overlap when in use, so as not to form overheated areas and affect the life. Pay attention not to break the porcelain parts, so as not to expose the electric heating material and affect the safety.

4.The workpiece to be heated must be reliably grounded. The operating voltage shall not exceed 1.05 times of the customized voltage.

5.LCD crawler ceramic heater is the use of high strength, good thermal radiation performance of lead oxide ceramic elements as insulation material with high quality nickel-chromium wire as the heating body, through the heater can be rectangular or triangular.

6.The nickel-chromium wire and wire are welded with a new process, and the welded joints are all buried in the ceramic elements and the insulation is reliable. The ceramic heater and the control equipment are equipped with a complete heat treatment system, and their connection adopts a special connector, and the length of the wire can be configured according to the distance between the workpiece and the control equipment.

7.The length and size can be flexibly changed, and the crawler ceramic heater should be selected according to the geometry of the workpiece, wall thickness and heat treatment process.

8.The length and size of the tracked ceramic heater can be flexibly changed, and the corresponding specifications should be selected according to the geometry of the workpiece, wall thickness and heat treatment process.

Product Parameter

|

Production Code |

Description |

Standard Size |

|

XTCP0101 |

Ceramic Heater CP3 (60V,2.7KW) |

75mm×660mm/pc |

|

XTCP0102 |

Ceramic Heater CP4 (60V,2.7KW) |

100mm×495mm/pc |

|

XTCP0103 |

Ceramic Heater CP6 (60V,2.7KW) |

150mm×330mm/pc |

|

XTCP0104 |

Ceramic Heater CP8 (60V,2.7KW) |

205mm×250mm/pc |

|

XTCP0105 |

Ceramic Heater CP10 (60V,2.7KW) |

255mm×205mm/pc |

|

XTCP0106 |

Ceramic Heater CP12 (60V,2.7KW) |

305mm×165mm/pc |

|

XTCP0107 |

Ceramic Heater CP15 (60V,2.7KW) |

380mm×145mm/pc |

|

XTCP0108 |

Ceramic Heater CP16 (60V,2.7KW) |

405mm×125mm/pc |

|

XTCP0109 |

Ceramic Heater CP21 (60V,2.7KW) |

535mm×100mm/pc |

|

XTCP0110 |

Ceramic Heater CP24 (60V,2.7KW) |

610mm×85mm/pc |

|

XTCP0111 |

Ceramic Heater CP48 (60V,2.7KW) |

1220mm×45mm/pc |

|

XTCP0112 |

Ceramic Heater CP10 (60V,2.7KW) |

255mm×85mm/pc |

Shipment

provides customers with quality and safe transportation.

Sensing the Temperature: The thermostat in an immersion heater utilizes advanced temperature sensors such as thermistors or bi-metallic strips to constantly mon...

READ MORESinton, a global manufacturer of industrial heating systems, has officially released a new technical white paper titled “Fundamentals of Organic Heat Carrier Bo...

READ MOREOil Quality Management The foundation of contaminant control in an oil circulation heater lies in maintaining high-quality circulating oil. The performance and ...

READ MOREIn the context of the global energy and chemical industry's continuous transformation towards safety, efficiency and intelligence, China's high-end industrial e...

READ MOREOrganized fire safety drills To enhance safety awareness within the industrial park and in response to the "119" Fire Safety Awareness Month, on November 29th,...

READ MORE