WhatsApp: +86-185-5601-8866

Heating Equipment

2025-03-04

In many scenarios, maintaining a specific temperature is critical to equipment operation, product quality, and the comfort of life. As a highly efficient electric heating product, the heat tracing tape quietly plays a key role. Today, let us have an in-depth understanding of Sinton tropical technology products.

How it Works:

The heat tracing tape is divided into two kinds: self-limiting temperature and constant power. The core of the self-limiting temperature heat tracing tape is a special polymer material containing polymer matrix and conductive medium, which can conduct electricity and heat at normal temperature. When the temperature rises, the expansion of the polymer causes the distance between the conductive medium to increase and the resistance to increase. According to Joule's law, heat production decreases; otherwise, the heat production increases, and the power temperature control can be automatically adjusted. The constant power heat tracing tape is composed of heating core wire, etc., and the current heats through the resistance wire, which is heated according to Joule's law.

Product features:

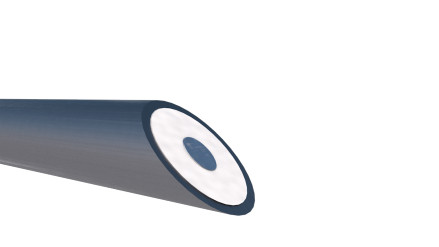

1. Structure: The inner layer is conductive thermal plastic, and the outer layer is double-layer flame-retardant polyolefin with shielding layer

2, temperature range: maximum exposure temperature 85℃, maximum operating temperature 65±5℃, minimum operating temperature -60℃

3, construction temperature: minimum: -5℃

4, thermal stability: from 10℃ to 99℃ after 300 cycles back and forth, the heat of the tropical zone is maintained at more than 90%.

5, bending radius: 20℃ at room temperature 25.4mm-30 ℃ at low temperature 35.0mm

6. Insulation resistance: When the length of the tropical zone is 100m and the ambient temperature is 20 ° C, the minimum value of the insulation resistance (between the wire and the shield) is 20MΩ

7. Starting current (10℃) 0.4A per meter

8. Please refer to some precautions for installation and use

9, the maximum length: not more than 100 meters

Categories:

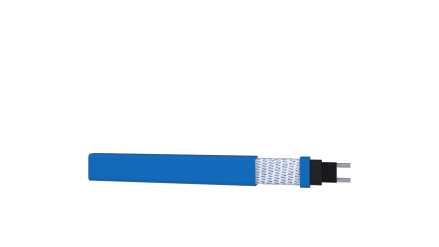

Self-controlled temperature

As the temperature rises, the resistance becomes smaller, because the current is larger when it is started, the length of use is generally not more than 100 meters, and the tropical belt can be cut at will, no matter how long, the rated voltage can be heated.

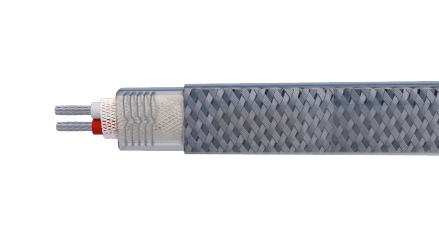

Parallel type

Two (or three) parallel insulated copper stranded wires are used as power busbars. The PTC characteristic heating wire is wound on the skeleton, and the bus is alternately connected every other heating section length to form a continuous parallel resistance. The length of the tracing wire is about 10-800 meters.

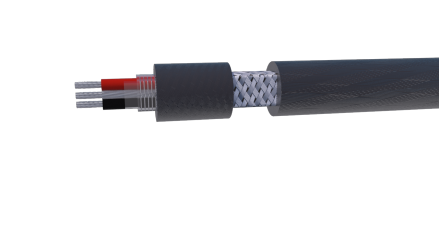

Tandem type

Three parallel insulated copper stranded wires with the same cross-section area and a certain length are used as power busbars and heating cores, one end of which is reliably shorted, and the other end is connected to 380V (or designed voltage) power supply to form a star-shaped load, according to Joule-Lenz's law: Q=0.24IRT Electrical energy into thermal energy Star load continuously emits heat, forming a continuous, uniform heating of the electric tracing zone. According to the actual situation, the three phases (single phase) of the electric tracing belt can be separated (split type), and can also be integrated into one. The length of the use of this tropical zone can not be too short, generally using about 500-2500 meters.

High temperature electricity

This tropical belt is made of glass fiber or other high temperature resistant materials, temperature resistance within 300℃, the length of 1-50 meters.

Silicone rubber electricity

This heating belt can be used for the heating, tracing and insulation of industrial equipment or laboratory pipe boxes, tanks and tanks, oil drums (tanks) in humid, non-explosive gas sites. The length of the heating belt is 1-15 meters.

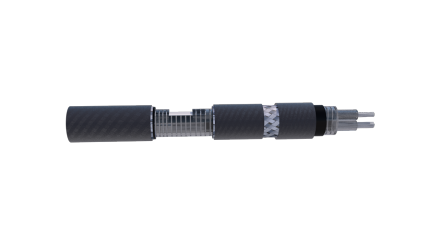

MI heating cable

The heating cable is a metal wire core (heating body), the core is closely surrounded by mineral magnesium oxide (insulation layer) and metal tube (usually copper, steel or stainless steel, etc.) after many draws, continuous working temperature can reach 250-590℃, short-term working temperature can reach 1083℃, so that the length of 18-680 meters.

Applications:

1. Industry: In petrochemical industry, heat pipelines and storage tanks for crude oil and chemical raw materials to maintain the fluidity and quality of the medium;

In the power industry, steam, water pipes and instrument pipelines are heated to ensure the normal operation of equipment;

In the field of iron and steel metallurgy, it is used for cooling water pipeline, gas pipeline and hot metal ladle, etc., to ensure equipment stability and production safety.

2. Building and municipal: in terms of building water supply and drainage, it is installed on the pipes in outdoor or non-heating areas to prevent water pipes from freezing and cracking and ensure water supply.

The selection of tropical zone needs comprehensive consideration:

1. Environment: According to the lowest and highest ambient temperature, select the tracking zone to avoid low temperature failure and high temperature damage; High protection grade products for humid environment, prevent short circuit; Where there is a corrosive medium, choose a corrosion-resistant outer sheath with tropical.

2. Pipes or equipment: metal pipes conduct heat quickly, select high-power tracing tropics, and plastic pipes are the opposite; Large size, high power, long tracking; Where the shape is complex, use products with good flexibility.

3. Medium: According to the medium type and temperature requirements, determine the maintenance temperature of the tracing zone to ensure that the medium remains in a proper state.