WhatsApp: +86-185-5601-8866

Heating Equipment

News

2024-04-02

In the industrial field, flanges are an important element of connecting pipes and equipment, and in the world of flanges, GB, JB, HG three standards are guidelines that cannot be ignored. At the same time, different types of flanges, such as flat welded flanges, neck flat welded flanges, socket welded flanges, neck butt welded flanges and flange covers, provide a rich choice for engineering. Sinton will delve into these standards and types, as well as their corresponding code names, to reveal the colorful world of Flanges for you.

First, let's look at the three major standards of GB, JB and HG. GB is the national standard, JB is the Ministry of Machinery standard, HG is the Ministry of chemical industry standard. These three standards serve different fields, ensuring that flanges are widely used in all walks of life. GB standard has been widely recognized in engineering projects with its national authority, JB standard focuses more on mechanical engineering, and HG standard plays an important role in the chemical industry. Understanding these standards helps engineers make informed choices based on specific needs.

Next, let's focus on the type of flange. Flat welded flange, neck welded flange, socket welded flange, neck butt welded flange and flange cover, each type has its own unique characteristics and application scenarios.

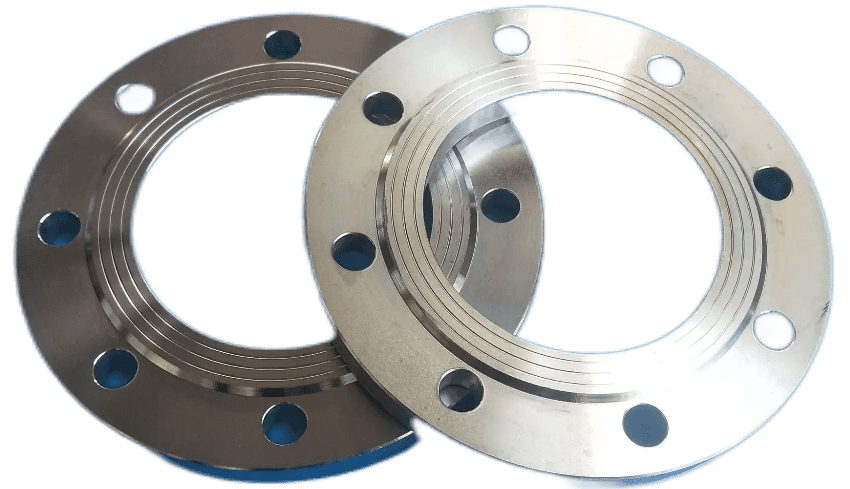

Flat welded flange: flat welded flange is also known as lap welded flange, the connection of the flat welded flange and the pipe is to insert the pipe into the inner hole of the flange to the appropriate position, and then lap welded, its advantage is that the welding assembly is easier to align and the price is cheap, so it is widely used. According to the internal pressure calculation, the strength of the flat welded flange is about two-thirds of the relative welding flange, and the fatigue life is about one-third of the butt welded flange. Therefore, the flat welded flange is only suitable for the pipeline system where the pressure level is relatively low and the pressure fluctuation, vibration and shock are not serious. (Advantages: suitable for general engineering, easy installation, low cost);

Neck flat welded flange: The neck flat welded flange is the same as the plate flat welded flange, and the steel pipe, pipe fittings, etc. are inserted into the flange through the fillet weld and the equipment or pipe connection flange. Flat welded flange with neck is also a flat welded flange, because it is short neck, thus improving the strength of the flange and improving the bearing force of the flange. So it can be used for higher pressure pipeline equipment manufacturers. (Advantages: good rigidity and sealing, often used in high temperature and high pressure environment);

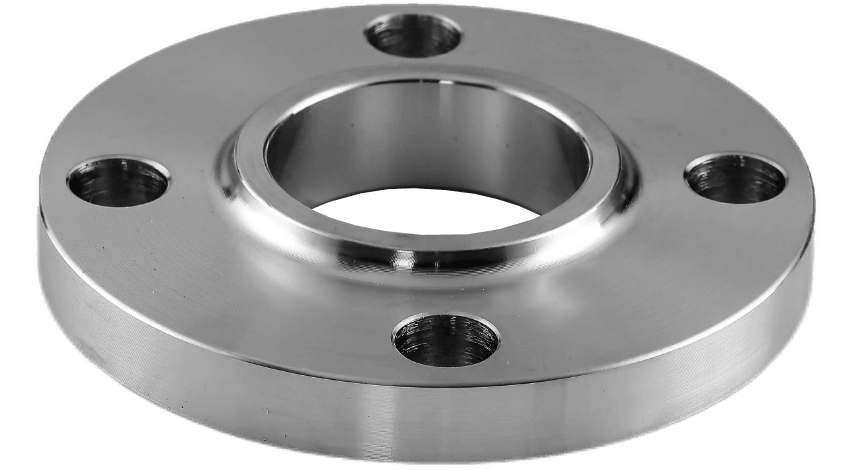

Socket welding flange: The socket welding flange is a flange with one end and the other end of the pipe welded with bolts. It is commonly used in pipelines with PN≤10.0Mpa and DN≤40. (Advantages: easy to install, suitable for low pressure system, is one of the common flange types);

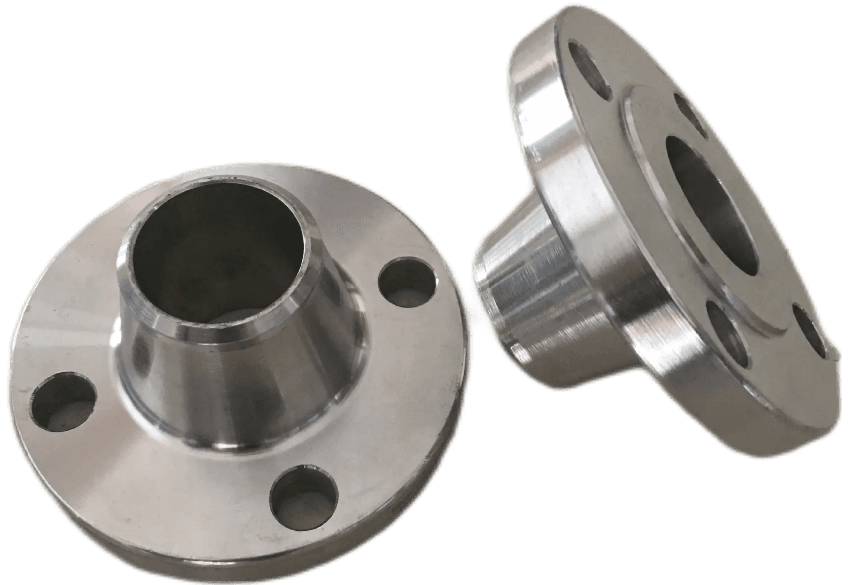

Neck butt welded flange: neck butt welded flange is also known as high neck flange, it is different from other flanges in that there is a long and inclined high neck from the flange and pipe welding to the flange, the wall thickness of this section of high neck gradually transitions to the wall thickness along the height direction, improving the stress discontinuity, thus increasing the strength of the flange. Neck butt welding flange is mainly used in harsh working conditions, such as pipe thermal expansion or other loads to make the flange subjected to greater stress, or stress changes repeatedly occasions; Pressure, temperature fluctuates greatly pipeline and high temperature, high pressure and sub-zero low temperature pipeline. (Advantages: suitable for high temperature and high pressure conditions, with good corrosion resistance);

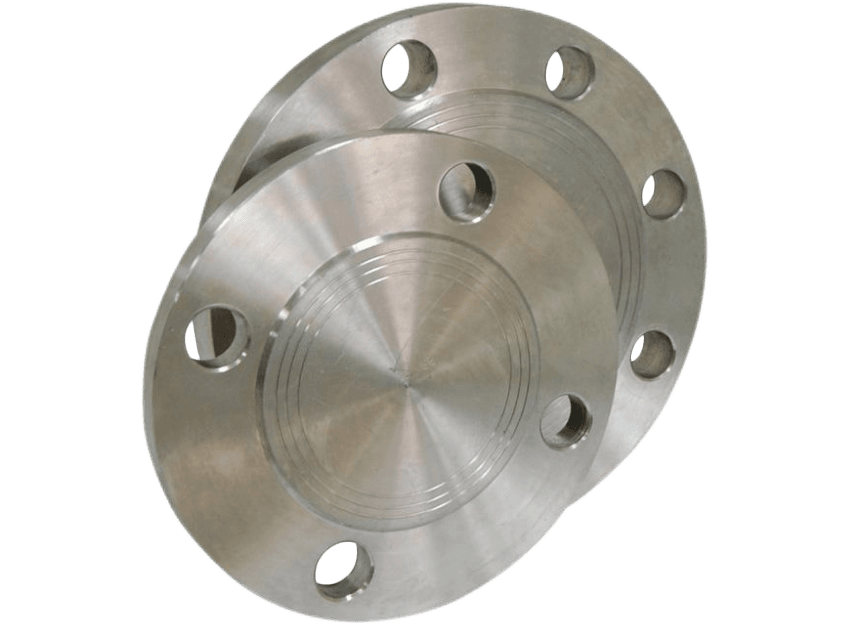

Flange cover: Flange cover is also called blind flange, blind plate. It is a flange without a hole in the middle for sealing the pipe plug. The function is the same as the welded head and the wire cap, but the blind flange and the cap can be removed at any time, and the welded head is not. Practical application in the heating industry to do welding heating tube or heat exchange equipment welding heat exchange tube is more used. (Advantage: Used to close the flange connection, to protect the pipeline and equipment from the external environment).

Each type of flange has its corresponding code name, which is the common language of engineers. Familiarity with these codes allows for faster and more accurate selection of the appropriate flange. For example, the flange code under the GB standard, the flange code under the JB standard, and the flange code under the HG standard, all have their own characteristics, reflecting their good performance in their respective fields.

In the world of flanges, GB, JB, HG three standards provide a solid foundation for engineering, and different types of flanges provide a wide range of options for engineers. With a deep understanding of these standards and types, engineers can be more flexible in addressing engineering challenges and ensuring safe and reliable operation of pipelines and equipment. Flanges connect every part of the industrial world and become an indispensable part of the project.

Looking For Business Opportunity?

Request for a call today

WhatsApp: +86-185-5601-8866

Tel: +86-185-5601-8866

E-mail: [email protected]

Address: Sinton Building, No. 886 Yandu Road, Yandu District, Yancheng City, Jiangsu Province

Friendly Link: www.cn-lvdao.com www.sealing-china.com

Products

Message