Heating Equipment

Hot air circulation oven is a kind of drying equipment widely used in industrial production. It heats the air through a heating tube, and then uses a circulating fan to make the hot air constantly circulate in the oven, so as to achieve uniform heating and drying of the material.

The working process of hot air circulation oven mainly includes the following steps:

Heating: Through the heating tube to convert electrical energy into heat energy, so that the air temperature in the oven rises.

Circulation: The circulation fan continuously blows hot air into the oven to form circulating hot air.

Heat transfer: The hot air is in contact with the material, and the heat is transferred to the material, so that the water in the material evaporates.

Moisture removal: The evaporating water is discharged out of the oven with the hot air, so as to achieve the drying of the material.

details

Advantage:

1. Good temperature uniformity: due to the continuous circulation of hot air in the oven, all parts of the material can be heated evenly and improve the drying quality.

2. High drying efficiency: hot air circulation can speed up the evaporation of water, shorten the drying time, and improve production efficiency.

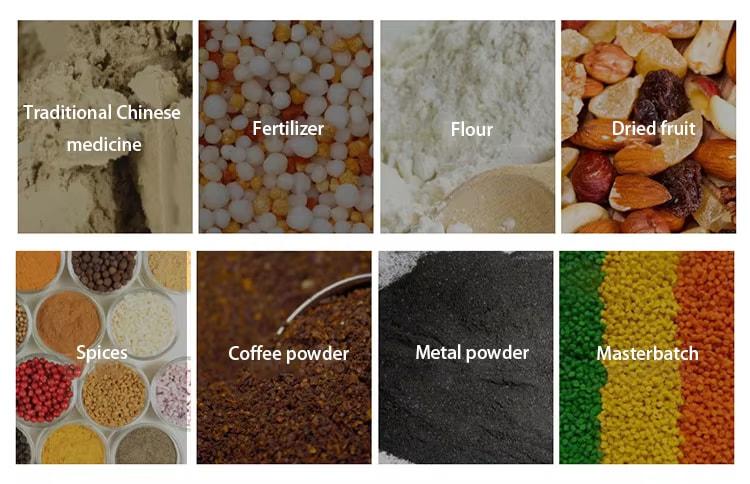

3. Wide range of application: It can be used for drying materials of different shapes, sizes and properties, such as powder, particles, block materials, etc.

4. Easy operation: automatic control or manual control, simple and convenient operation, easy to master.

5. Energy saving and environmental protection: Reasonable structural design and good insulation performance can reduce heat loss and reduce energy consumption.

Technical parameter:

1. Temperature related parameters:

Temperature range: Common room temperature + 10 ° C to 200 ° C, room temperature + 10 ° C to 300 ° C, room temperature + 10 ° C to 400 ° C and other different temperature range options, depending on the use of the oven and application scenarios. For some ovens with special requirements, the temperature range may be higher, such as 500 ° C, 800 ° C or even 1200 ° C.

Temperature control accuracy: generally can reach ±0.5 ° C to ±2.5 ° C (full scale), this parameter reflects the accuracy of the temperature control of the oven, the higher the accuracy, the smaller the temperature fluctuation in the oven, the more conducive to the accurate drying or heat treatment of the material.

Temperature fluctuation: usually between ±0.5 ° C and ±2 ° C, refers to the fluctuation range of the internal temperature of the oven at the set temperature, the smaller the fluctuation, the better the temperature stability of the oven.

Heating rate: for example, the time required to rise from room temperature to 100 ° C is generally about 10 minutes, but different specifications and power ovens will vary, and the heating rate can improve production efficiency.

2. Structure size parameters:

Inner box size: that is, the space size used to place materials inside the oven, usually expressed in the form of width × depth × height, such as 45×40×40cm, 60×50×90cm, etc., the size of the inner box size should be selected according to the volume and quantity of drying materials required in actual production.

External size: refers to the overall external size of the oven, also expressed in the form of width × depth × height, the size of the external size is related to the installation space and placement of the oven.

Pan size (if any) : If the oven is equipped with a pan, the size of the pan such as length, width, height and the number of layers also need to be considered, the pan size and the number of layers will affect the amount of material per drying.

3. Air supply system parameters:

Circulation mode: Common are forced horizontal air supply cycle, vertical circulation and so on. Forced circulation can make the hot air distribution in the oven more uniform, improve the drying effect.

Fan parameters: include the type of the fan (such as turbofan, centrifugal fan, etc.), power, and air volume. The performance of the fan determines the speed and effect of the hot air circulation, the greater the power and the greater the air volume, the better the effect of the hot air circulation, but at the same time it will consume more energy.

4. Heating system parameters:

Heating heat source: electric heating, steam heating, far infrared heating, electric steam dual use and so on. The electric heating method has fast heating speed and convenient control, but high energy consumption; Steam heating is relatively energy efficient, but requires a steam supply system; Far infrared heating has the advantages of high heating efficiency and strong penetration of materials.

Heating power: According to the size and temperature requirements of the oven, the heating power will vary, generally between a few kilowatts and tens of kilowatts.

5. Electrical system parameters:

Power supply: There are different power types such as single-phase three-wire 220V and three-phase five-wire 380V, which need to be selected according to the actual production site and power supply.

Control mode: can be divided into manual control and automatic control. Automatic control is usually controlled by PID microcomputer, which can realize automatic constant temperature, rapid temperature compensation, timing and other functions, and the operation is more convenient and accurate.

6. Other parameters:

Uniformity: the temperature uniformity of no-load is generally about ±2 ° C, the higher the uniformity, the more consistent the heating degree of the material in the oven, the better the drying effect.

Noise: reflects the noise level when the oven is running, and generally requires the noise to be within a certain range to reduce the impact on the working environment.

Insulation performance: The material and thickness of the insulation layer will affect the insulation performance of the oven, and good insulation performance can reduce the loss of heat and reduce energy consumption.

Application:

1. Pharmaceutical industry: used for the drying of drugs, Chinese medicinal materials, raw materials, etc.

2. Food industry: used for drying food, fruits, vegetables, tea, etc.

3. Chemical industry: used for drying chemical raw materials, plastic particles, rubber products, etc.

4. Electronic industry: Used for the drying of electronic products, electronic components, etc.

5. Other industries: Hot air circulation ovens can also be used for drying wood, paper, textiles and other industries.

Shipment

provides customers with quality and safe transportation.

Sensing the Temperature: The thermostat in an immersion heater utilizes advanced temperature sensors such as thermistors or bi-metallic strips to constantly mon...

READ MORESinton, a global manufacturer of industrial heating systems, has officially released a new technical white paper titled “Fundamentals of Organic Heat Carrier Bo...

READ MOREOil Quality Management The foundation of contaminant control in an oil circulation heater lies in maintaining high-quality circulating oil. The performance and ...

READ MOREIn the context of the global energy and chemical industry's continuous transformation towards safety, efficiency and intelligence, China's high-end industrial e...

READ MOREOrganized fire safety drills To enhance safety awareness within the industrial park and in response to the "119" Fire Safety Awareness Month, on November 29th,...

READ MORE