Heating Equipment

Sinton, a proxy designation for a wide-ranging consortium of enterprises, encompassing those focused on thermal solutions, measurement, and control technologies, presents an extensive array of products and services. These encompass sophisticated heating elements and systems engineered for accurate temperature regulation to technical support and bespoke engineering solutions intended for the enhancement of industrial processes.

The focus is placed on the pivotal role played by these Sinton products in the efficient functionality of heating systems within industrial environments. They deliver localized, precise heating essential for various applications, including, but not limited to, the warming of metal components, process heating, and the temperature regulation of crucial parts in manufacturing and production lines.

Sinton's contributions stand out particularly in the realms of:

·Customizability: Proposing solutions that are adaptable to the specific requisites of an application, guaranteeing good performance.

·Efficiency: Accentuating products crafted for heightened efficiency, which can precipitate considerable energy savings and diminished operational expenses.

·Reliability: Guaranteeing the robustness and longevity of heating systems, pivotal for the sustenance of uninterrupted industrial processes. Technical Support: Supplying exhaustive support and resources, like technical libraries, CAD drawings, and engineering tools, to aid in the formulation and execution of efficacious heating solutions.

details

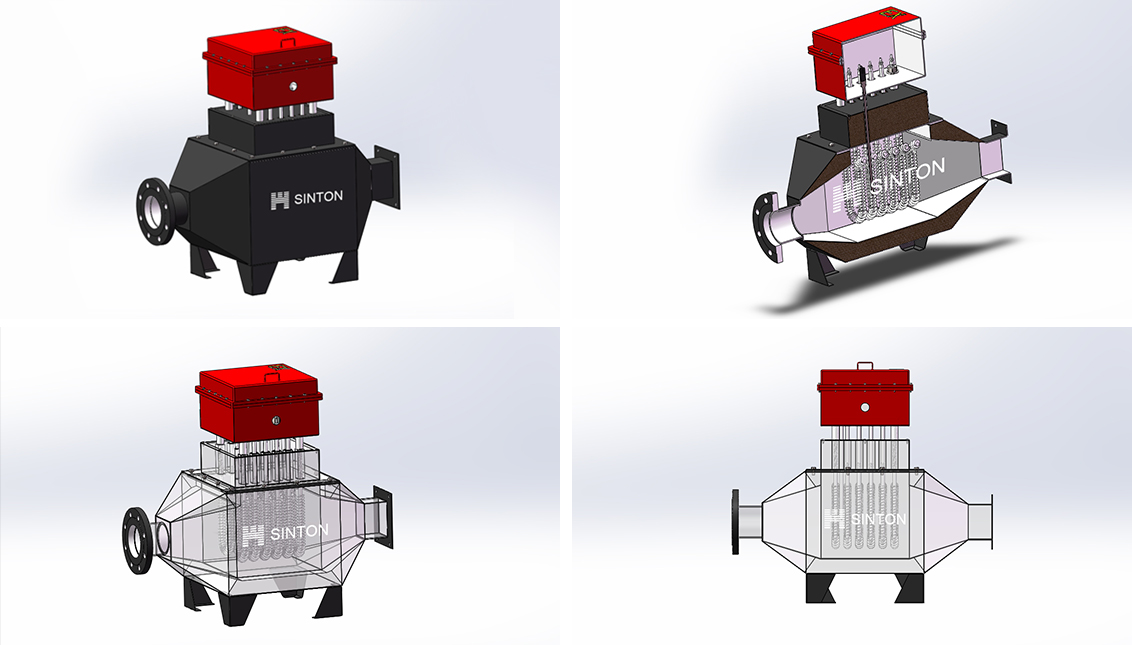

Industrial and Agricultural Drying Room Heating Air Duct Tube Heater, as a high-efficiency heating equipment specially designed to meet the heating needs of industrial and agricultural drying rooms, has advanced thermodynamic principles and can heat the air to The required temperature is transported to the drying room through the air duct to achieve the purpose of drying the materials. The product has reasonable design and high thermal efficiency, which can quickly heat up in a short time, save energy consumption and reduce production costs.

In order to achieve a more precise temperature control effect, the heater is equipped with an intelligent temperature control system. Users can set the temperature according to actual needs, thereby achieving precise temperature control and ensuring the drying effect. At the same time, high-quality insulation materials are used inside the heater to ensure safe operation of the equipment. In addition, in order to prevent safety accidents caused by overheating of the equipment, the heater also has an overheat protection function.

The product has a compact design and small size, making it easy to install in the drying room. At the same time, the equipment is easy to maintain and has a long service life. This makes this heater ideal for use in a variety of industrial and agricultural drying rooms. Whether it is grain drying, fruit and vegetable drying or wood drying, it can meet the drying needs of different industries.

A broad array of configurations in industrial air duct heaters is available to accommodate diverse applications, featuring open coil, tubular, and finned tubular designs. Acknowledging the unique necessities of each industrial application, Sinton extends comprehensive customization opportunities. This encompasses adjustable wattage, voltage specifications, heater dimensions, alongside the incorporation of sophisticated temperature control mechanisms for meticulous heating administration.

Product Parameter

| Model | Power | Inner Chamber size | Diameter of air outlet |

| KW | MM | MM | |

| FD-10 | 10 | 300*300*300 | DN100 |

| FD-20 | 20 | 500*300*300 | DN200 |

| FD-30 | 30 | 400*400*400 | DN300 |

| FD-40 | 40 | 500*400*400 | DN300 |

| FD-50 | 50 | 600*400*400 | DN350 |

| FD-60 | 60 | 700*400*400 | DN350 |

| FD-80 | 80 | 700*400*500 | DN350 |

| FD-100 | 100 | 900*400*500 | DN350 |

| FD-120 | 120 | 1000*400*500 | DN350 |

| FD-150 | 150 | 700*750*500 | DN400 |

| FD-180 | 180 | 800*750*500 | DN400 |

| FD-240 | 240 | 1000*750*600 | DN500 |

| FD-300 | 300 | 1200*750*600 | DN500 |

| FD-360 | 360 | 1000*800*900 | DN500 |

| FD-420 | 420 | 1200*800*900 | DN500 |

| FD-480 | 480 | 1400*800*900 | DN500 |

| FD-600 | 600 | 1600*1000*1000 | DN600 |

| FD-800 | 800 | 1800*1000*1000 | DN600 |

| FD-1000 | 1000 | 2000*1000*1000 | DN600 |

details

details

The versatility of Sinton air duct heaters allows for their application across multiple industrial uses, notably:

·Heating processes within manufacturing setups

·Air pre-heating in HVAC systems for sizable industrial edifices

·Drying and curing operations in the pharmaceutical, food, and painting sectors

·Chemical processing that necessitates exact temperature regulation

Shipment

provides customers with quality and safe transportation.

Sensing the Temperature: The thermostat in an immersion heater utilizes advanced temperature sensors such as thermistors or bi-metallic strips to constantly mon...

READ MORESinton, a global manufacturer of industrial heating systems, has officially released a new technical white paper titled “Fundamentals of Organic Heat Carrier Bo...

READ MOREOil Quality Management The foundation of contaminant control in an oil circulation heater lies in maintaining high-quality circulating oil. The performance and ...

READ MOREIn the context of the global energy and chemical industry's continuous transformation towards safety, efficiency and intelligence, China's high-end industrial e...

READ MOREOrganized fire safety drills To enhance safety awareness within the industrial park and in response to the "119" Fire Safety Awareness Month, on November 29th,...

READ MORE