WhatsApp: +86-185-5601-8866

Heating Equipment

2024-11-29

Liquid electric heating tube selection guidance - design prerequisites

Before designing a liquid electric heating tube, we must understand several things:

① The heating liquid situation, whether it is heated water, oil or corrosive liquid;

② The pressure required after the liquid electric heating tube is loaded into the equipment;

③ Installation mode: horizontal installation or vertical installation;

④ Installation space size;

⑤ Material of the installation container;

Liquid electric heating tube selection guidance - material selection

The material selection of the sheath of the liquid electric heating tube is mainly determined by the situation of the heating liquid, and can generally be selected according to the following material:

▲ The situation of heating water

|

material |

Be suitable for |

|

Stainless steel 304 |

Non-corrosive, softened water |

|

Stainless steel 316L |

Heated drinking water |

|

Stainless steel 304+ anti-scale coating |

In the case of hard water quality, the anti-scale coating process is mainly divided into: liquid coating and electrostatic powder coating |

|

Stainless steel 310S/Incoloy |

High-end products, anti-scale and anti-corrosion |

▲ The situation of heating oil

|

material |

Be suitable for |

|

Carbon steel |

General heat transfer oil, lubricating oil, etc |

|

Stainless steel 304 |

General heat transfer oil, lubricating oil, etc |

|

Stainless steel 304+ anti-scale coating |

General oil is not a good heat conduction oil, lubricating oil, etc |

Liquid electric heating tube selection guidance - the choice of heating tube style

General liquid electric heating tube style selection according to power to choose, common styles:

1.Threaded single head electric heating pipe

2.U-shaped or shaped (on request)

3.Hexagonal thread thread electric heating pipe

4.Electric heating tube with threaded thread with adjustable temperature control

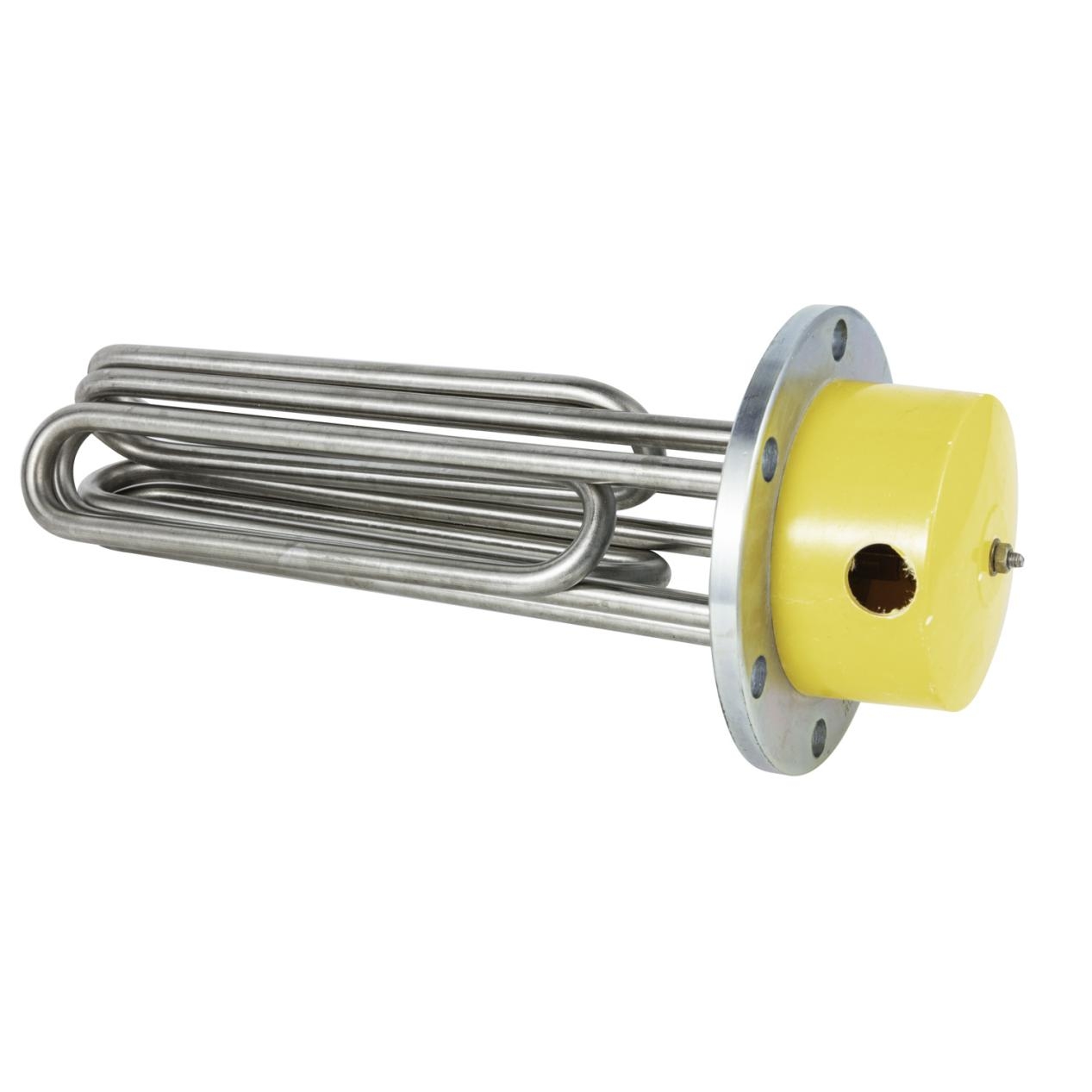

5.Flat flanged electric heating tube

Liquid electric heating tube selection guidance - power design

Without considering the heat loss, it can be calculated by the following formula;

The calculation formula is: required power (kw) = weight of water (kg) * Temperature difference * specific heat capacity of water {kJ/(kg·℃)} / time (seconds)

For example:

For example, if the initial temperature is 10℃, what is the power of the electric heating tube required for heating 500kg of water to 90℃ with 60mins (3600s)?

Required power (kw) = weight of water (kg) * Temperature difference * specific heat capacity of water {kJ/(kg·℃)} / time (seconds)

Total power = 500*(90-10)*4.17/3600=46.33kw

Taking into account the heat loss, the general design power is larger than that calculated by the formula.

Liquid electric heating tube selection guidance - heating tube surface load design

Core concept: The higher the surface load, the worse the life of the electric heating tube; Therefore, reasonable surface load design is the most important. (For ease of understanding, we simplify the surface load to power per meter.)

|

Heating medium |

Recommended power per meter |

|

Closed oil tank heating oil Y1 |

1KW/ m |

|

Flowing or circulating oil Y2 |

2KW/ m |

|

Tap water S1 |

2-3KW/ m |

|

Purified water S2 |

3-4KW/ m |

Note: Each meter here refers to the length of the heating zone of the heating tube. The recommended power per meter is not absolute.

Liquid electric heating tube selection guidance - use attention points

1. Do not use unstable containers. Before installing electric heating pipes, ensure that the containers are placed smoothly, and then install and secure them. Because the container that is not placed smoothly is easy to overturn, pour liquid, resulting in dry burning of the electric heating pipe, because of its fire, electric shock and other dangers;

2. Do not place the electric heating tube in a heating container that lacks oil and is stained. Place the electric heating tube in an oil with more impurities to heat it, which is easy to cause damage to the electric heating tube due to carbon formation on the surface and the heat generated by itself cannot be dissipated in time (if the scale is more serious, the coating can be used to treat the heating tube). At the same time, it is also necessary to ensure that the heating liquid must not be lower than the normal liquid level standard, otherwise it may also damage the heating pipe, fire and other dangers;